Cranes Inspection Checklist – Creating a thorough cranes inspection checklist is essential for ensuring safety and compliance with regulations. The checklist should cover various aspects of the crane, including structural integrity, mechanical components, safety features, and operational aspects. Here’s a detailed cranes inspection checklist:

Cranes Inspection Checklist

Pre-Operational Inspection

1. General Condition

- Inspect for visible damage or cracks in the structure.

- Check for any signs of rust, corrosion, or wear.

2. Controls and Indicators

- Test all control buttons, levers, and indicators.

- Ensure that all warning lights and alarms are functioning correctly.

3. Hydraulic Systems

- Check hydraulic fluid levels.

- Inspect hoses, lines, and fittings for leaks or wear.

4. Electrical Systems

- Verify that all electrical connections are secure.

- Check the condition of wiring and insulation.

5. Lubrication

- Ensure that all moving parts are properly lubricated.

- Check lubricant levels and add as needed.

6. Safety Devices

- Test the emergency stop button.

- Inspect limit switches and load indicators.

- Ensure anti-two block devices are operational.

Operational Inspection

1. Load Hooks

- Inspect hooks for cracks, deformation, or excessive wear.

- Ensure safety latches are functioning properly.

2. Wire Ropes and Chains

- Check for fraying, kinks, or broken wires.

- Inspect end connections and fittings.

3. Boom and Jib

- Inspect for straightness and structural integrity.

- Check for any signs of bending, cracking, or corrosion.

4. Load Block and Sheaves

- Inspect sheaves for proper alignment and wear.

- Check that the load block moves freely.

5. Outriggers and Stabilizers

- Ensure outriggers are fully extended and locked.

- Check for any signs of damage or improper deployment.

Post-Operational Inspection

1. Operational Performance

- Evaluate the crane’s performance during operation.

- Note any unusual noises or vibrations.

2. Brake Systems

- Test the functionality of all braking systems.

- Check for proper brake adjustment and wear.

3. Operational Environment

- Ensure the operating area is free of hazards.

- Verify that proper signals and communication were used.

Documentation

1. Inspection Records

- Record the date and time of the inspection.

- Note the inspector’s name and any findings.

2. Maintenance Log

- Update the maintenance log with any repairs or adjustments made.

- Schedule any necessary follow-up inspections.

Regulatory Compliance

1. Certification

- Verify that the crane has current inspection and certification.

- Ensure compliance with relevant safety regulations (e.g., OSHA, ANSI).

2. Operator Training

- Confirm that the crane operators are properly trained and certified.

- Ensure that training records are up-to-date.

Additional Considerations

1. Weather Conditions

- Check the crane’s suitability for operation in current weather conditions.

- Adjust operational practices based on environmental factors.

2. Site-Specific Factors

- Consider any site-specific hazards or requirements.

- Adapt the inspection checklist as needed for special conditions or uses.

This checklist should be used regularly to ensure the crane remains in safe operating condition. Regular inspections and maintenance are crucial for preventing accidents and ensuring the longevity of the equipment.

Cranes Inspection Checklist

Following are the check book list of Cranes Inspection Checklist-

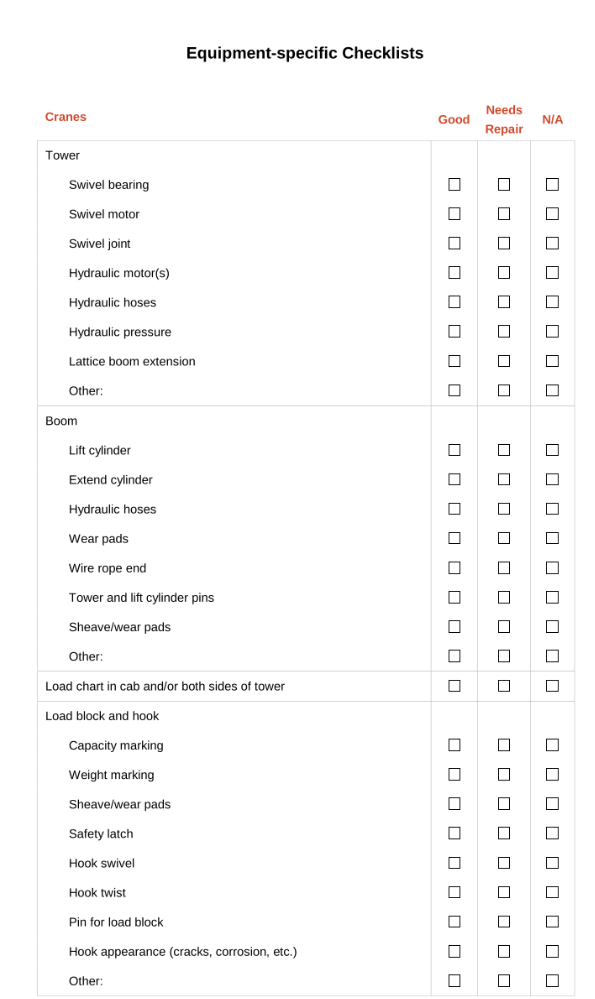

Equipment-Specific Checklists

Cranes

| Component | Good | Needs Repair | N/A |

|---|---|---|---|

| Outriggers | |||

| Pad Condition | [ ] | [ ] | [ ] |

| Outrigger Function | [ ] | [ ] | [ ] |

| Beams | [ ] | [ ] | [ ] |

| Outrigger Lock | [ ] | [ ] | [ ] |

| Hydraulic Hoses | [ ] | [ ] | [ ] |

| Other: | [ ] | [ ] | [ ] |

| Grab Rails/Steps/Platforms | [ ] | [ ] | [ ] |

| Safety Pressure Relief Valves | [ ] | [ ] | [ ] |

| Other: | [ ] | [ ] | [ ] |

| Other: | [ ] | [ ] | [ ] |

Tower

| Component | Good | Needs Repair | N/A |

|---|---|---|---|

| Swivel Bearing | [ ] | [ ] | [ ] |

| Swivel Motor | [ ] | [ ] | [ ] |

| Swivel Joint | [ ] | [ ] | [ ] |

| Hydraulic Motor(s) | [ ] | [ ] | [ ] |

| Hydraulic Hoses | [ ] | [ ] | [ ] |

| Hydraulic Pressure | [ ] | [ ] | [ ] |

| Lattice Boom Extension | [ ] | [ ] | [ ] |

| Other: | [ ] | [ ] | [ ] |

Boom

| Component | Good | Needs Repair | N/A |

|---|---|---|---|

| Lift Cylinder | [ ] | [ ] | [ ] |

| Extend Cylinder | [ ] | [ ] | [ ] |

| Hydraulic Hoses | [ ] | [ ] | [ ] |

| Wear Pads | [ ] | [ ] | [ ] |

| Wire Rope End | [ ] | [ ] | [ ] |

| Tower and Lift Cylinder Pins | [ ] | [ ] | [ ] |

| Sheave/Wear Pads | [ ] | [ ] | [ ] |

| Other: | [ ] | [ ] | [ ] |

Load Chart in Cab and/or Both Sides of Tower

| Component | Good | Needs Repair | N/A |

|---|---|---|---|

| Load Chart | [ ] | [ ] | [ ] |

Load Block and Hook

| Component | Good | Needs Repair | N/A |

|---|---|---|---|

| Capacity Marking | [ ] | [ ] | [ ] |

| Weight Marking | [ ] | [ ] | [ ] |

| Sheave/Wear Pads | [ ] | [ ] | [ ] |

| Safety Latch | [ ] | [ ] | [ ] |

| Hook Swivel | [ ] | [ ] | [ ] |

| Hook Twist | [ ] | [ ] | [ ] |

| Pin for Load Block | [ ] | [ ] | [ ] |

| Hook Appearance (Cracks, Corrosion) | [ ] | [ ] | [ ] |

| Other: | [ ] | [ ] | [ ] |